BFSI Bioblend Tree-Free Paper

The Federal Government’s paper consumption varies from year to year, but it is generally estimated that it consumes about 20 billion sheets of copy paper annually. In an attempt to reduce paper consumption, Executive Order 13693 confirmed past mandates requiring federal agencies to acquire paper with at least 30% post-consumer recycled content and to enable duplex printing. Duplex printing is a good example of behavioral changes people can take to reduce the environmental impact associated with paper consumption, but there are also opportunities for reduction from the product choices. 30% post-consumer content paper still consists of 70% virgin tree-fiber, which in the case of the Federal Government translates to 1.7 million trees cut down annually. The paper industry is evolving to reduce the environmental impact of paper, increasing recycled content and, in some cases, eliminating tree usage entirely.

On February 21, 2012, President Obama released the memorandum “Driving Innovation and Creating Jobs in Rural America through Biobased and Sustainable Product Procurement.” The memorandum affirmed federal procurement requirements for biobased products already established by the 2002 Farm Bill (See Toolbox). Heartened by the memorandum, knowing that the Federal government would favor biobased products, Bert and Maria Herring founded BioFiber Solutions International (BFSI) in August 2012. With nearly forty years of experience in the office products industry, Herring recognized the opportunity to repurpose agricultural and consumer waste to support federal biobased procurement requirements.

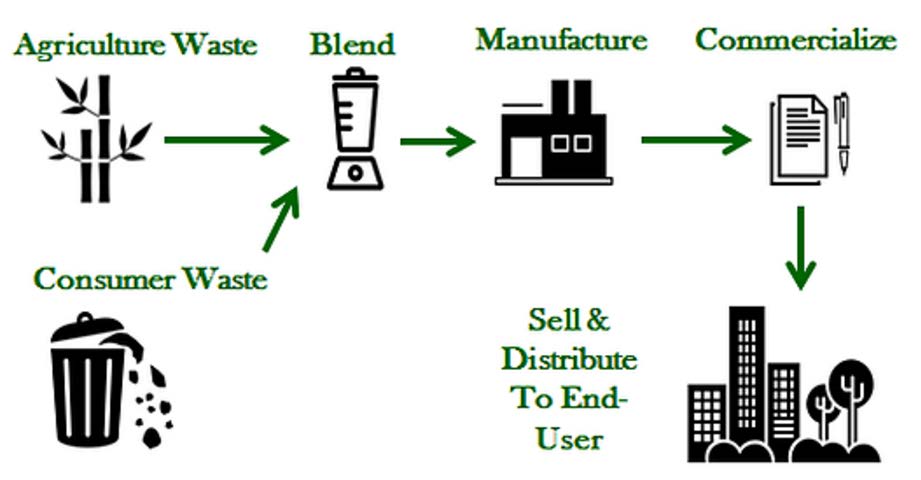

BSFI developed its unique BioBlend technology to create tree-free, biobased paper products. BioBlend pulp is 30% derived from sugarcane bagasse, the fibrous waste leftover after sugarcane stalks are crushed, and 70% derived from post-consumer waste. All of BSFI’s end-products are made in the United States and Certified BioPreferred products by the U.S. Department of Agriculture (USDA).

With limited tree-free, biobased alternatives on the market, BSFI convinced manufacturing partners to invest in BioBlend product lines. Knowing that regulations guaranteed a substantial potential customer in the Federal Government, BSFI worked around the diagram from the end-user backwards to the manufacturer. Herring explained, “We sold the customer first and then worked our way back to the distributors and manufacturers. The risk was mitigated in the minds of the distributors and manufacturer because their customers were already identified and ready to buy.” BFSI works with established distributors and manufacturers in the office products industry to convert some of their existing product lines into BioBlend lines including: Essendant, Smead Manufacturing, and Roaring Spring Paper Products, also a dominating force in the Collegiate Market.

Once the BioBlend Line of office products were developed, BSFI approached Office Depot Office Max and several other top dealers to sell and distribute the products because of their Federal Strategic Sourcing Initiative (FSSI) contracts. The General Services Administration (GSA) awards FSSI contracts to ease procurement and to leverage the purchasing power of the Federal Government. Without BFSI’s USDA BioPreferred Certifications and without the support of Office Depot Max and FSSI dealer community it would have been extremely difficult for federal procurement officers to acquire much less know about BioBlend products. Herring explained, “We figured out how to get our products manufactured and sold through existing infrastructure. The real key is putting the pieces together, connecting the dots. If they can’t get [the product], what good is it?” In addition to the Federal Government, BFSI is making inroads in the private sector through collaborations with manufacturing partners and distributors.

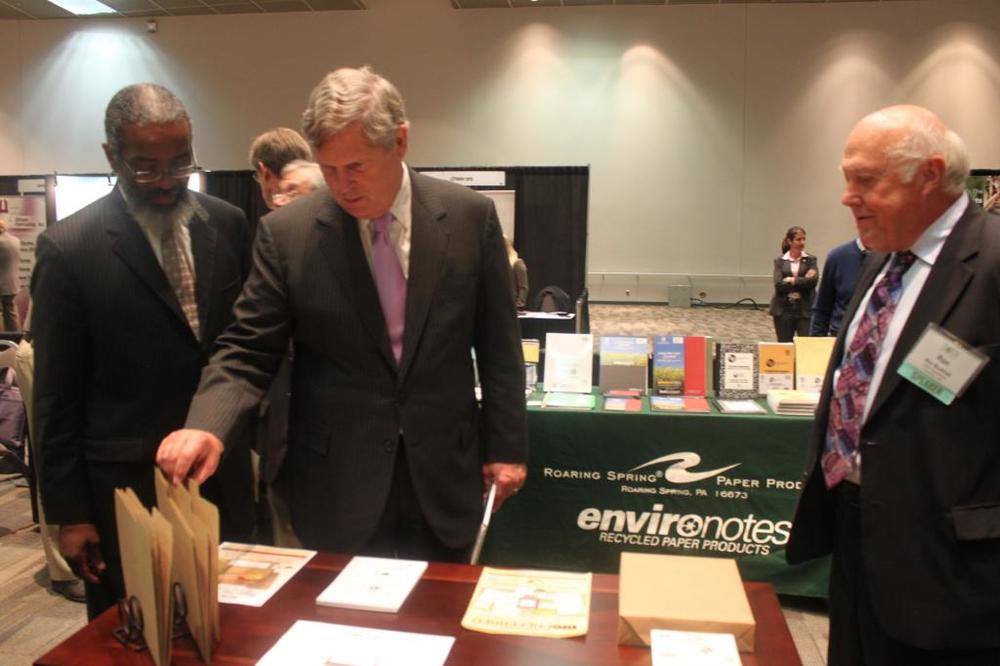

BFSI in the USDA BioPreferred pavilion sponsored by Office Depot Max at the OBIC bioproducts show at Ohio State University. Left to right: Assistant Secretary for Administration Dr. Gregory Parham, Secretary of Agriculture Tom Vilsack examining certified file folders from Smead Manufacturing and Director of the Biopreferred program Ron Buckhalt. BFSI’s other partner’s booth, roaring spring, is also pictured in the background and with their products on display.

BFSI in the USDA BioPreferred pavilion sponsored by Office Depot Max at the OBIC bioproducts show at Ohio State University. Left to right: Assistant Secretary for Administration Dr. Gregory Parham, Secretary of Agriculture Tom Vilsack examining certified file folders from Smead Manufacturing and Director of the Biopreferred program Ron Buckhalt. BFSI’s other partner’s booth, roaring spring, is also pictured in the background and with their products on display.

Moving Forward

Herring shared an acronym he uses when he and his associates Christian Johnson and Kaitlyn Herring evaluate potential new products: MVPSA.

M: is for margin. BFSI must ensure the products they develop make money along the supply chain for themselves and for those with whom they collaborate. However, without a domestic pulp source, production costs are increased. Though Herring would like to establish a business capable of using the agricultural waste available right here in the U.S., developing the appropriate infrastructure to produce high quality paper from an alternative pulp source will be a daunting task. Until then, it translates into higher costs and higher prices for the potential end-users.

V: is for Value. Many times, end-users pay slightly higher prices for environmentally superior products. Herring confirmed that one of the major challenges for the BioProducts Industry is “getting the American customer to place a dollar value on the environmental benefits of these products” To aid in this endeavor, BSFI employs an Eco-Calculator to “enable any business or institution to easily calculate the environmental benefits achievable by switching to high performance tree-free BioBlend copy paper.” The eco-calculator estimates the potential trees saved, tons of greenhouse gases mitigated, gallons of water conserved, pounds of agricultural residue recovered, pounds of solid waste not produced, the social cost of carbon savings, and LEED credits. The USDA, for example, has over 100,000 employees. Using a conservative estimate that USDA employees use only half the paper of the average U.S. office worker, 10-reams of 30% recycled copy paper annually, the calculator found that USDA could save over 42,500 trees and repurpose 1.5 million pounds of agricultural residue. The eco-calculator also estimates the monetary savings associated with the environmental benefits, helping businesses better evaluate the true value of switching to BioBlend.

P: is for Performance. Performance is indispensable at BFSI. As a small business with an alternative product, they must produce paper that works as well or better than traditional paper. Skepticism among new buyers is common due largely to past product experiences. Herring observed, “People have long memories and some of the old products did not work as well.” To refute old sentiments, BFSI encourages potential customers to test products before purchasing and to run copy paper through their machines, proving that BFSI’s products work in real office settings. Achieving the proper structure of paper using alternative pulp sources is a difficult process and one that BFSI and partners will have to continue to perfect, especially if they are successful in acquiring a local pulp source.

S: is for Sustainable Materials and A is for American Made. BFSI prides itself on repurposing agricultural and consumer waste in a way that protects the environment and creates U.S. jobs. Herring repeatedly stressed his company’s desire to support rural America by participating in this new biobased market, directly aligning with the mission of USDA’s BioPreferred Program. According to Herring, acquiring USDA’s BioPreferred Certification “offered an opportunity for small companies like ours.” The label creates awareness for new lines of sustainable, biobased paper products in an, until recently, traditional industry. Herring added, “We might be a gnat, but our model has the potential for achieving [USDA’s goals] in a big way.”

Herring estimates that the Federal Government will purchase about 16,800 cases of BioBlend paper this year, less than 0.0042% of its annual consumption. While this may be minimal for the Federal Government, it is significant for one small business leveraging the BioPreferred label and federal procurement mandates. BFSI has a long road ahead and ambitious plans to expand and improve. When asked what was on the horizon for BFSI, Herring exclaimed, “The sky is the limit! Right now we have about thirty items that we are making and, if you think about it, that doesn’t even scratch the surface of the paper products we could make.”

© The George Washington University. All Rights Reserved. Use of copyrighted materials is subject to the terms of the Licensing Agreement.